Get Lost Wax Casting Parts From China Manufacturers and Suppliers.

Investment casting is a manufacturing process in which a liquid material, typically wax, is used to create a mold for a casting. The mold is then coated in a refractory material and heated to remove the wax, leaving a cavity in the shape of the desired part. Molten metal is then poured into the cavity, where it solidifies and takes on the shape of the mold. This process is commonly used to produce complex parts with tight tolerances, such as those used in pumps and valves. Investment casting is favored in these industries due to the ability to produce intricate shapes and fine details in a single step, which can help reduce overall production costs and lead time.

Investment casting is a common manufacturing process used to produce high precision components for pump and valve applications. In investment casting, a wax pattern of the desired component is created, coated with a refractory material, and then heated to remove the wax and form a ceramic mold. Molten metal is then poured into the mold to create the final component. This process offers excellent dimensional accuracy and surface finish, making it suitable for complex shapes and thin-walled components. Additionally, investment casting can produce components with a high degree of consistency and repeatability, making it a popular choice for applications that require tight tolerances and high performance.

If you are looking for lost wax casting suppliers in China, you are in the right spot. We are a very professional supplier of lost wax casting equipment,

We supply our Lost Wax Casting overseas: Egypt, Turkey, Viet Nam, Philippines, Brazil, Pakistan, India, Mexico。Our showroom location: Egypt, Italy, France, Germany, Philippines, Peru, Indonesia, Pakistan.

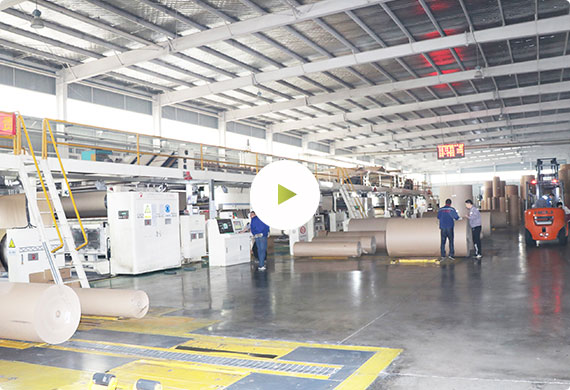

An investment casting factory produces precision metal components using the investment casting process. This process involves creating a wax pattern of the desired part, coating it with a ceramic material, and then melting away the wax and firing the ceramic mold to harden it. The mold is then filled with molten metal, which solidifies and takes the shape of the pattern. After cooling, the ceramic mold is broken away to reveal the cast metal component. The investment casting process is commonly used to produce complex, high-precision parts for a variety of industries, including aerospace, medical, and power generation.